What Can This Equipment Do? Freeze-Drying Already in Use in European-Scale Research

In the article series “What Can This Equipment Do?”, we present laboratory infrastructure acquired within the project “Strengthening the Capacity of the Latvian State Institute of Wood Chemistry to Participate in International Cooperation Projects.” (No. 1.1.1.2/1/25/I/003) These instruments are not merely technical upgrades – they are strategic tools that enable the Institute to engage fully in high-level international consortia, develop new research themes in bioeconomy, materials science and environmental technologies, and provide partners with precise and reproducible experimental solutions.

This article focuses on a freeze-drying system that is already being used in the major European project 4Sir2.

Technology in Practice: Experience from the 4Sir2 Project

The Latvian State Institute of Wood Chemistry is a partner in the project Building a Healthy Drink Ecosystem to Prevent Childhood Obesity (4Sir2), which aims to develop a functional beverage for children with overweight using grape or apple juice enriched with resveratrol and polyphenols derived from grape-processing by-products.

These compounds can influence gene expression related to metabolic regulation, while the project concept simultaneously addresses two socially significant challenges: tackling childhood obesity and promoting sustainable food production based on circular-economy principles.

The project brings together 16 partners from nine countries and is coordinated by the Polish Pro-Akademia Research and Innovation Centre (Centrum Badań i Innowacji Pro-Akademia). Universities, research institutes, agricultural organisations and food companies from Poland, Latvia, Portugal, Germany, Belgium, Italy, Greece, the United Kingdom and Moldova have joined forces within the consortium.

Within the project, the Latvian State Institute of Wood Chemistry contributes as a technology developer and sustainability assessor for beverages, drawing on its expertise in polymer technologies and life-cycle assessment (LCA). In the project, the tasks are related to monitoring the chemical composition to assess the impact of the drying process and the content of biologically active substances in grape residues. The Latvian coordinator is the Institute’s Scientific Director, Dr. sc. ing. Uģis Cābulis.

The project team also includes:

- Dr. chem. Māris Lauberts, who in Work Package 2 optimises drying technologies to preserve the biologically active compounds in grape pomace;

- PhD Anda Fridrihsone, who is responsible for sustainability assessment and impact analysis.

The Equipment in Operation

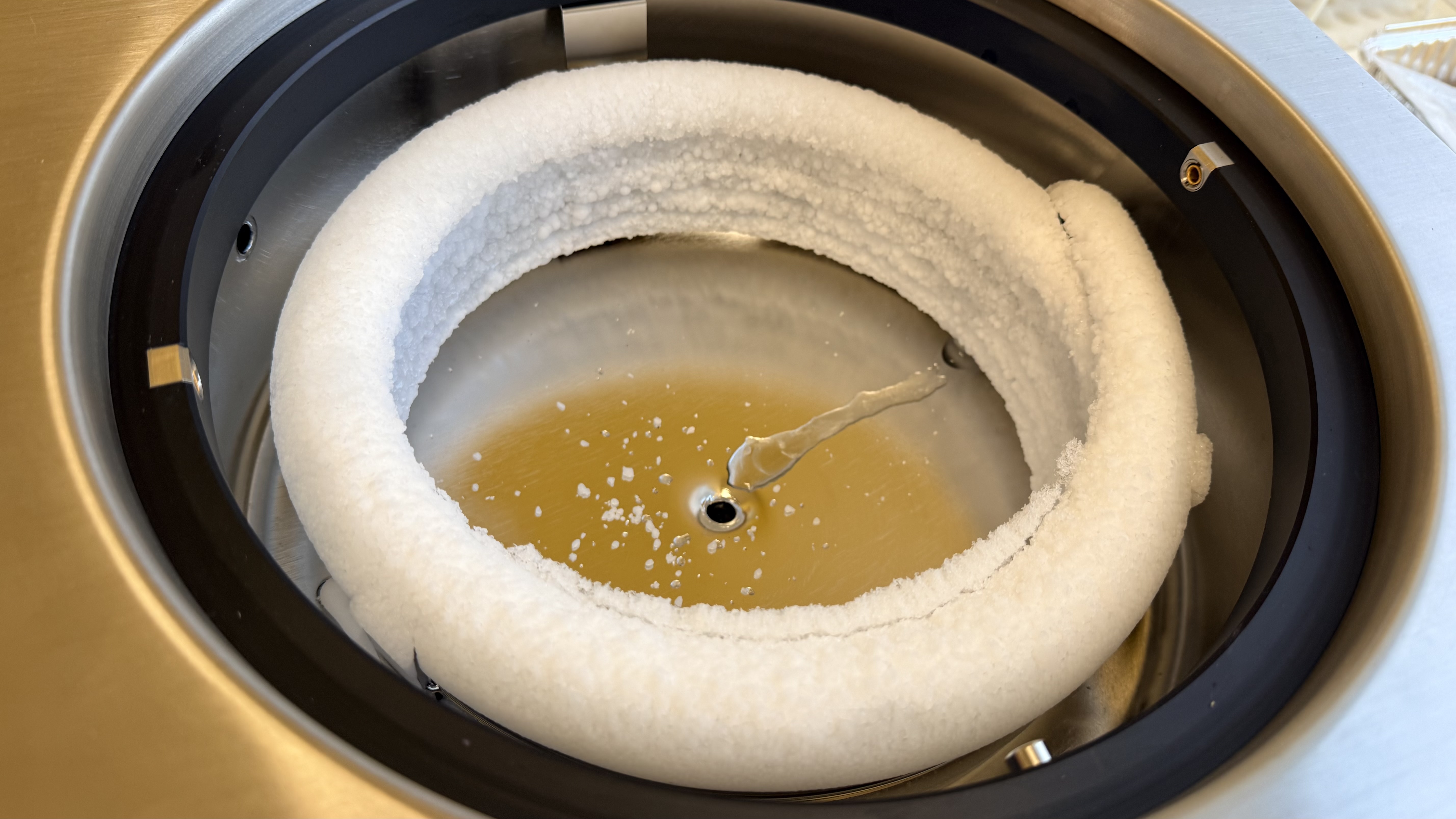

The photographs show laboratory work in which our senior researcher Dr. chem. Māris Lauberts removes freeze-dried grape-processing residues from the system – an everyday activity within the 4Sir2 project.

After the lyophilization process, Dr. chem. Māris Lauberts removes the acrylic dome from the Alpha 2-4 LSCplus unit to access the dried grape processing residues

This is where researchers evaluate how different drying approaches affect the stability, structure and potential application of polyphenols in functional beverages.

“Our aim is to preserve as many biologically active compounds as possible while ensuring a stable and reproducible process. This freeze-drying system allows us to control drying conditions very precisely and to compare different technological scenarios,” explains Dr. Māris Lauberts.

What Is Freeze-Drying and Why Is It Important?

Freeze-drying, or lyophilisation, is a process in which a sample is first frozen and then, under very low pressure, water transitions directly from the solid phase into vapour.

Compared with conventional thermal drying, freeze-drying better preserves biologically active substances, has minimal impact on sample structure, enables the production of stable products for long-term storage and ensures high reproducibility in scientific experiments.

This is crucial in food-innovation and bioeconomy projects, especially when working with sensitive plant extracts or naturally derived antioxidant fractions.

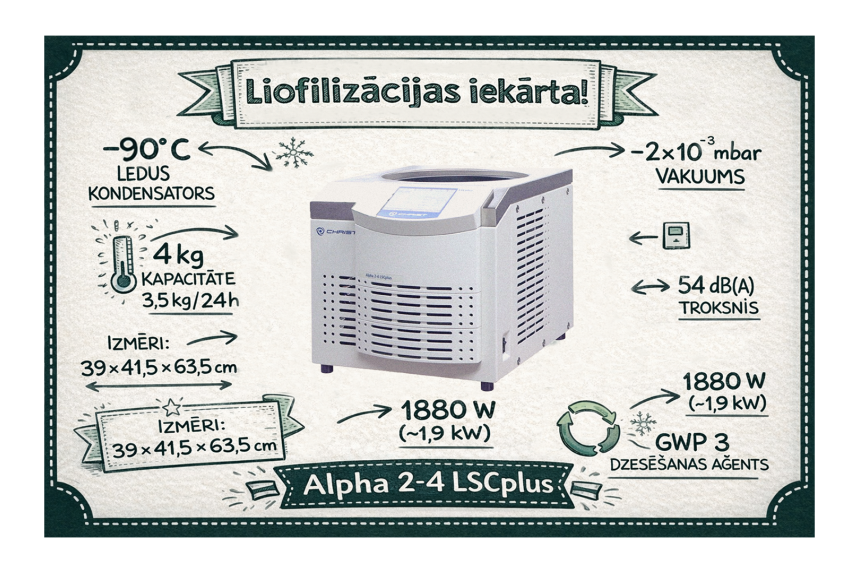

The lyophilization system enables deep freezing down to –90 °C.

What Exactly Can the New System Do?

The freeze-drying system installed at the Latvian State Institute of Wood Chemistry provides a high level of process control and flexibility. It enables deep freezing down to –90 °C and is equipped with sensors for monitoring vacuum, pressure and sample temperature, as well as for detecting the eutectic point. Uniform drying is ensured by heated shelves with homogeneous temperature distribution, while 32 storable programmes allow the automation of different process cycles. Data transfer is provided via network connectivity, and the system can be supplemented with a wide range of accessories for flasks, chambers and pilot-scale experiments.

Such technological equipment allows the system to be used not only in food research but also in biomaterials, wood chemistry and environmental-technology projects.

Strategic Infrastructure for Future Projects

The use of the freeze-drying system in the 4Sir2 project clearly demonstrates how infrastructure acquired through a capacity-building initiative is already delivering tangible benefits within Horizon Europe consortia.

It enables the Institute not only to implement current tasks at a high level, but also to demonstrate its strength as a partner in new international proposals in the fields of bioeconomy, food innovation and materials science. Such targeted investment in research infrastructure lays the foundation for long-term cooperation with leading European centres and strengthens the Institute’s ability to integrate fully into the European Research Area.