Rigid Polyurethane Foam as Cryogenic Insulation for Future Zero-Emission Commercial Aircraft (PUR4LH2)

The project addresses the challenge set by European civil aviation to develop a commercial aircraft powered by liquefied hydrogen (LH₂) by 2035. To meet the stringent requirements of the aviation industry, a rigid polyurethane foam composition will be developed for the cryogenic insulation of LH₂ tanks. The formulation will incorporate environmentally friendly, sustainable components—polyols derived from renewable raw materials, heavy metal-free catalysts, and low global warming potential (GWP) blowing agents.

The materials developed for aviation applications will be designed for a service life of at least 20 years. Additionally, methods for detecting and mitigating potential defects will be proposed.

The goal of PUR4LH2 is to develop a sustainable cryogenic insulation material with an emphasis on long-term durability. The raw materials used will be industrially produced, environmentally friendly, and have a low ecological footprint. These will include polyols derived from renewable resources, heavy metal-free catalysts, and state-of-the-art blowing agents. PUR4LH2 will be implemented in the following stages:

- Design, modeling, and formulation of the cryogenic insulation rigid polyurethane (PUR) foam composition;

- Production of PUR foams at laboratory and pilot scale; scaling up using representative models of cryogenic tank surfaces used in the aviation sector;

- Testing of insulation materials using standard testing equipment, as well as custom-designed cryogenic test rigs;

- Application of various accelerated artificial aging methods to predict material durability;

- Theoretical calculations and modeling of cryogenic insulation materials.

Project Implementation Timeline:

Project implementation started on January 1, 2025.

12 January 2026 – Project Progress Report for the Period 01 January 2025 – 31 December 2025

Project Objective:

The objective of PUR4LH2 is to develop sustainable cryogenic insulation with a focus on long-term durability. The raw materials to be used are industrially produced, environmentally friendly materials with a low ecological footprint. These include polyols derived from renewable feedstocks, heavy-metal-free catalysts, and next-generation blowing agents.

Current Project Activities

Activity 1: Production and Testing of PUR Foams at Laboratory Scale

Polyols derived from renewable resources or obtained through recycling processes have been selected and characterized. The hydroxyl number, acid number, viscosity, molecular weight, and functionality of the selected polyols were determined.

All selected polyols were tested in PUR foam systems. The foam rise rate and shrinkage after 24 hours were evaluated. For PUR foams with shrinkage not exceeding 5% after 24 hours, thermal and mechanical properties were determined.

Out of 70 tested PUR systems, 6 best-performing systems were selected for further testing, including foam production using a foaming machine and long-term storage tests.

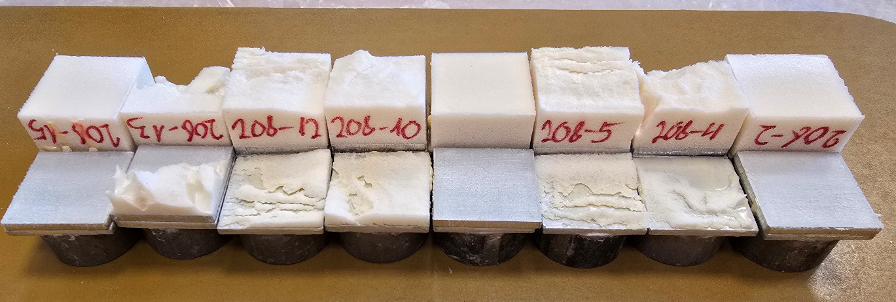

Image 1. PUR foam samples after adhesion testing

Activity 2: Production of PUR Foams at Pilot Scale and Testing of the Obtained Foams

Systems to be advanced to TRL 3 have been selected. The necessary system optimization has been carried out to enable PUR foam production using a foaming machine. This included optimization of catalysts and water content, as well as adjustment of the polyol system to isocyanate ratio.

Activity 3: Long-Term Storage Testing of Systems and Materials, Identification of Defects and Development of Corrective Solutions

Systems have been selected for long-term storage testing. The required calculations have been performed and a sampling schedule has been prepared.

Activity 6: Project Implementation and Dissemination of Results

During this reporting period, one scientific publication has been published:

Yakushin V., Dhalivala V., Vevere L., Cabulis U. Influence of Rigid Polyurethane Foam Production Technology on Cryogenic Water Uptake (2025) Polymers, 17(12), Article No. 1669. DOI: 10.3390/polym17121669.

Project results were presented at three international conferences:

PPS-40 (Polymer Processing Society), Auckland, New Zealand, 22–25 April 2025

New Capabilities and Countries in European Space Conference, Frascati, Italy, 13–16 May 2025

EASN 15th International Conference “Innovations in Aviation and Space Towards Sustainability Today and Tomorrow”, Madrid, Spain, 14–17 October 2025

The project progress and results were also presented at Shadow Day 2025, RTU Career Day 2025, Birch Day at the Latvian National Botanical Garden, and Researchers’ Night 2025.

Image 2. Staff of the LSIWC Polymer Laboratory with their Shadow Day participants

Image 3. L. Vēvere together with colleagues from the Laboratory of Lignin Chemistry at Birch Day at the Latvian National Botanic Garden

Image 4. Staff of the Polymer Laboratory at Researchers’ Night

Image 5. L. Vēvere at the EASN 15th International Conference “Innovations in Aviation and Space Towards Sustainability Today and Tomorrow”