TOMPosite

Project description

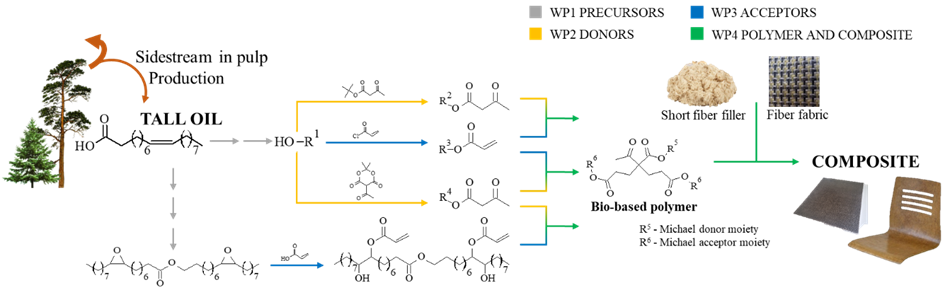

The main objective of TOMPosite project is to develop a thermoset two-component polymer resin with different crosslinking densities, suitable for developing composites with natural origin fibers, and reaching high (up to 90%) renewable material content and competitive characteristics. Pulp production side stream tall oil fatty acids (TOFA) and Meldrum’s acid synthesized from renewables will be utilized to synthesize the main components for polymer resin. The Michael nucleophilic addition will be exploited as a curing reaction for polymer matrix development. Two types of Michael donors will be synthesized by: converting TOFA-based polyols into acetoacetate by transesterification; cleavage of a Meldrum`s acid derivative with TOFA-based polyol. Two types of Michael acceptors will be obtained: by acrylation of TOFA-based polyols with acryloyl chloride; from epoxidized TOFA and TOFA-based fatty alcohol ester by oxirane ring opening with acrylic acid. Composites will be developed with reinforcement of natural origin short fibers and fabric. A schematic plan of the project is given in Figure 1.

Figure 1. Scheme of syntheses and work packages planned in the project

Project coordinator: Latvian State Institute of Wood Chemistry

Project partner: Riga Technical University

Implementation of the project

31.12.2025.

Project Progress Report for the Period 01.07.2025 – 31.12.2025 (7–12M)

Work has continued within the activities of WP1, WP2, WP5, and WP6. In accordance with the project plan, the implementation of WP3 has been initiated.

WP1 – Synthesis of Precursors for Michael Components

In addition to enzymatic epoxidation of tall oil, epoxidation using ion-exchange resins was also carried out. Oxirane rings were opened with butanediol and glycerol. The most suitable synthesis conditions were determined, and the obtained products were characterized (T1.1). The experimental work with Meldrum’s acid has been initiated (T1.2). Work is ongoing on the esterification of tall oil fatty acids with alcohols obtained via reduction (T1.3). For product characterization, epoxy value, hydroxyl value, acid value, viscosity, moisture content, and chemical structure were determined.

WP2 – Synthesis of Michael Donors

Michael donor synthesis using tert-butyl acetoacetate was performed for all polyols obtained in WP1 (T2.1), and the most suitable synthesis conditions were selected.

WP3 – Development of Michael Acceptors

The synthesis of Michael acceptors from tall oil polyols using acryloyl chloride has been initiated. Suitable synthesis methods, conditions, and solvents are being investigated (T3.1).

WP5 – Project Management

Work across all required project activities is being organized through coordination among the activity leaders. The necessary materials for project implementation have been ensured. A new employee, Laura Vasiļevska, has been hired and trained within the project.

WP6 – Exploitation and Dissemination

Laura Vasiļevska represented the TOMPosite project at the Researchers’ Night event. A corresponding post was published on the project’s Facebook page.

International scientific conferences to be attended in the coming year have been selected.

30.06.2025.

Project Progress Report for the Period 01.01.2025 – 30.06.2025 (0–6M)

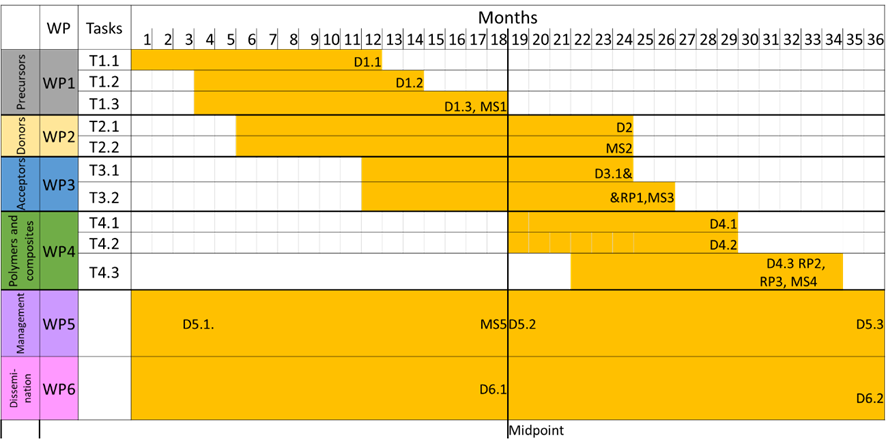

In accordance with the plan (see Fig. 2), activities for WP1, WP2, WP5, and WP6 have been initiated.

Figure 2. Project Gantt Chart

WP1 – Synthesis of Michael Component Precursors

Enzymatic epoxidation of tall oil and oxirane ring-opening with trimethylolpropane (TMP) has been performed (T1.1, see Fig. 3).

A literature review on Meldrum’s acid is underway (T1.2, T2.2).

A synthesis methodology has been developed for the reduction of tall oil fatty acids using LiAlH₄.

Preliminary experiments have been carried out to esterify the tall oil fatty acids with the alcohol obtained from the reduction (T1.3).

Figure 3. Synthesis of Michael Component Precursors (Alcohols).

WP2 – Synthesis of Michael Donors

Synthesis of Michael donors has been initiated using the raw materials obtained in WP1 activities with tert-butyl acetoacetate (T2.1).

WP5 – Project Management

The Data Management Plan has been created (Deliverable D5.1) and published on the Zenodo platform.

Technical specifications have been prepared and procurement processes initiated.

Several meetings with the project partner have been held (see Fig. 4).

Figure 4. TOMPosite team at the 6M project meeting at the Latvian State Institute of Wood Chemistry. From left: Ralfs Pomilovskis, Aiga Ivdre, Miķelis Kirpļuks, Inese Mieriņa.

WP6 – Exploitation and Dissemination of Results

- A dedicated section for the project has been created on the kki.lv website.

- The TOMPosite logo has been designed.

Several promotional posts were made on social media platforms – Facebook, LinkedIn, and Instagram. - We participated in several project dissemination events – RTU Career Days, and Shadow Day. In addition, TOMPosite staff from the Latvian State Institute of Wood Chemistry visited the Institute of Solid State Physics to discuss potential applications of TOMPosite polymer resins as well as joint project submissions (see Fig. 5).

Figure 5. TOMPosite team from the Latvian State Institute of Wood Chemistry visiting the Institute of Solid State Physics. From left: Ralfs Pomilovskis, Aiga Ivdre, Miķelis Kirpļuks.

01.01.2025.

The implementation of the project has started.