Pilot-Scale Hangar

In 2020, the Pilot-Scale Hangar of the Latvian State Institute of Wood Chemistry was opened, which promotes the commercialization of the technologies developed in our laboratories. Raw material preparation and material production sections, biorefining process workshop, which includes biomass hydrolysis, pyrolysis, extraction, are available in the hangar; carbonization; steam explosion equipment for biomass decomposition. Pilot facilities provide an opportunity to up-scale laboratory processes developed at LSIWC or at the Institute's cooperation partners, reaching technological readiness level (TRL) 4-6.

The hangar was built with the support of the European Regional Developmenet Fund project No. 1.1.1.4/17/I/013, 2017-2021, project leader Dr. Uģis Cābulis.

Available equipment

Material preparation:

- Coarse mill

- Vibrating mill

- High-capacity coarse sieve

- High-grade fine sieve

- Dryer

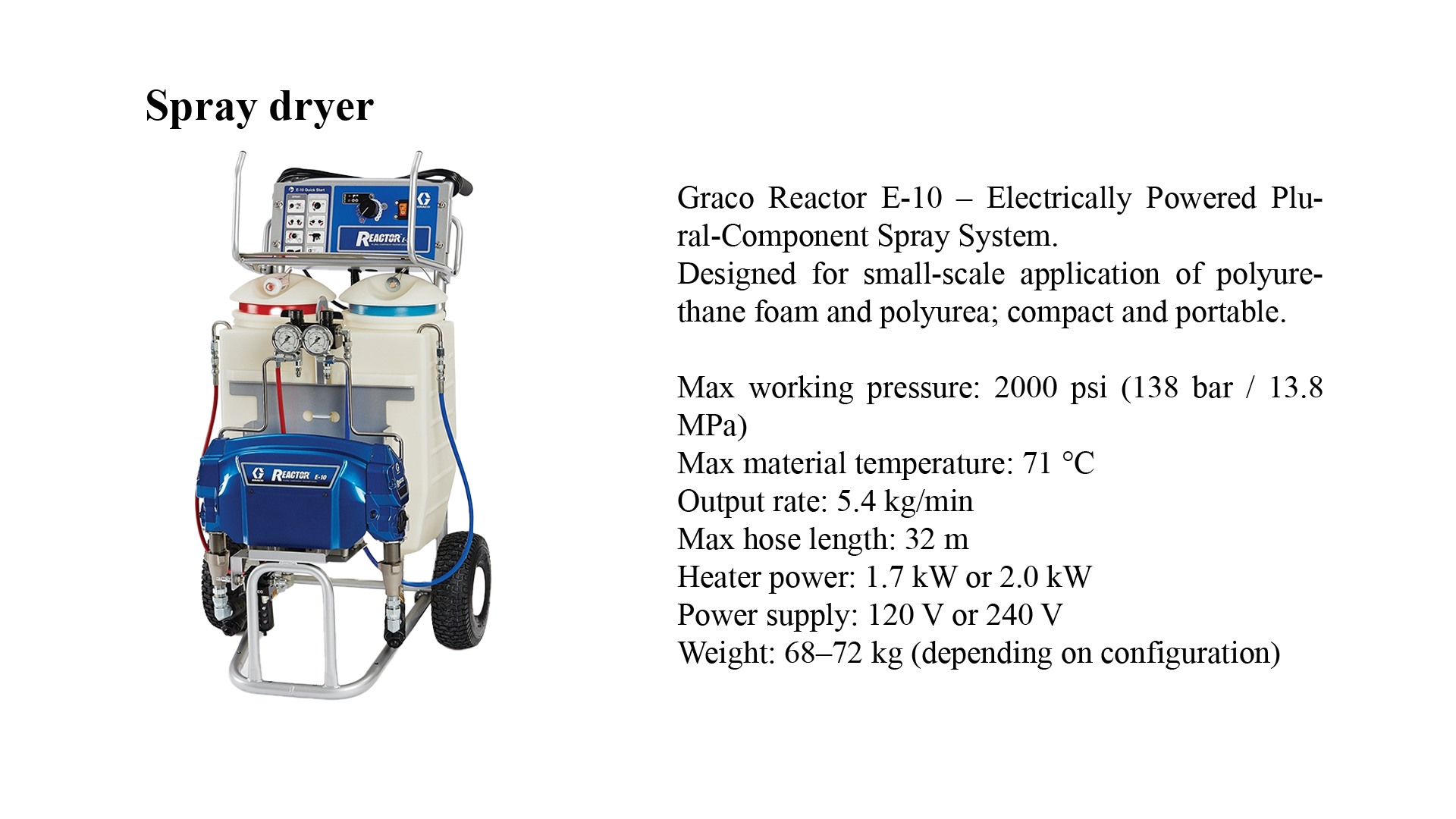

- Spray dryer

- Vacuum evaporator

- Filter press

- Climatic chamber

Biomass processing:

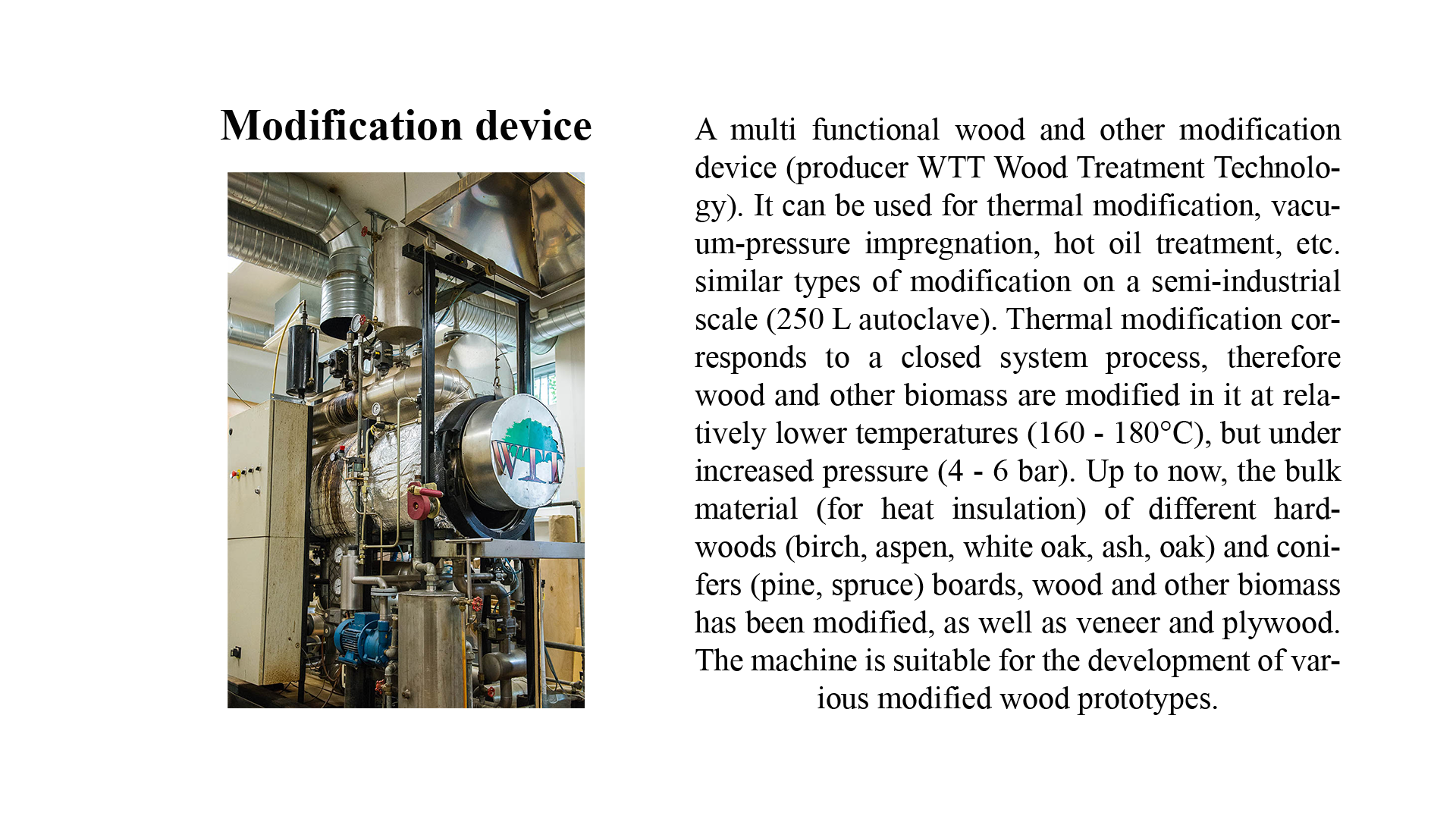

- Wood impregnation equipment

- Non-destructive testing machine

- Microscope with digital camera

- Mini reactor for synthesis in liquid medium with mechanical mixing

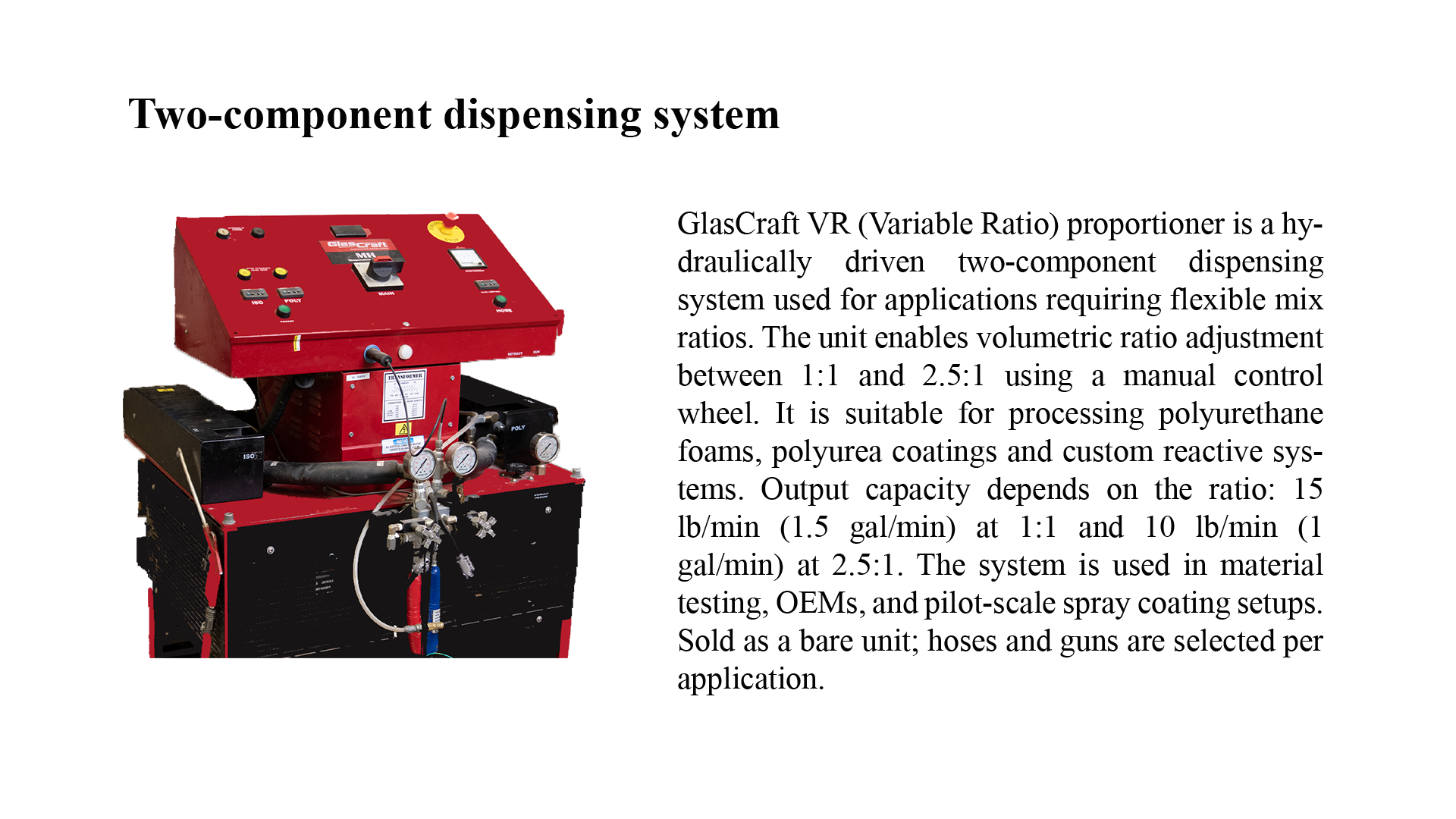

- Polyurethane production and test equipment

- Impact-tolerance measuring equipment with accessories

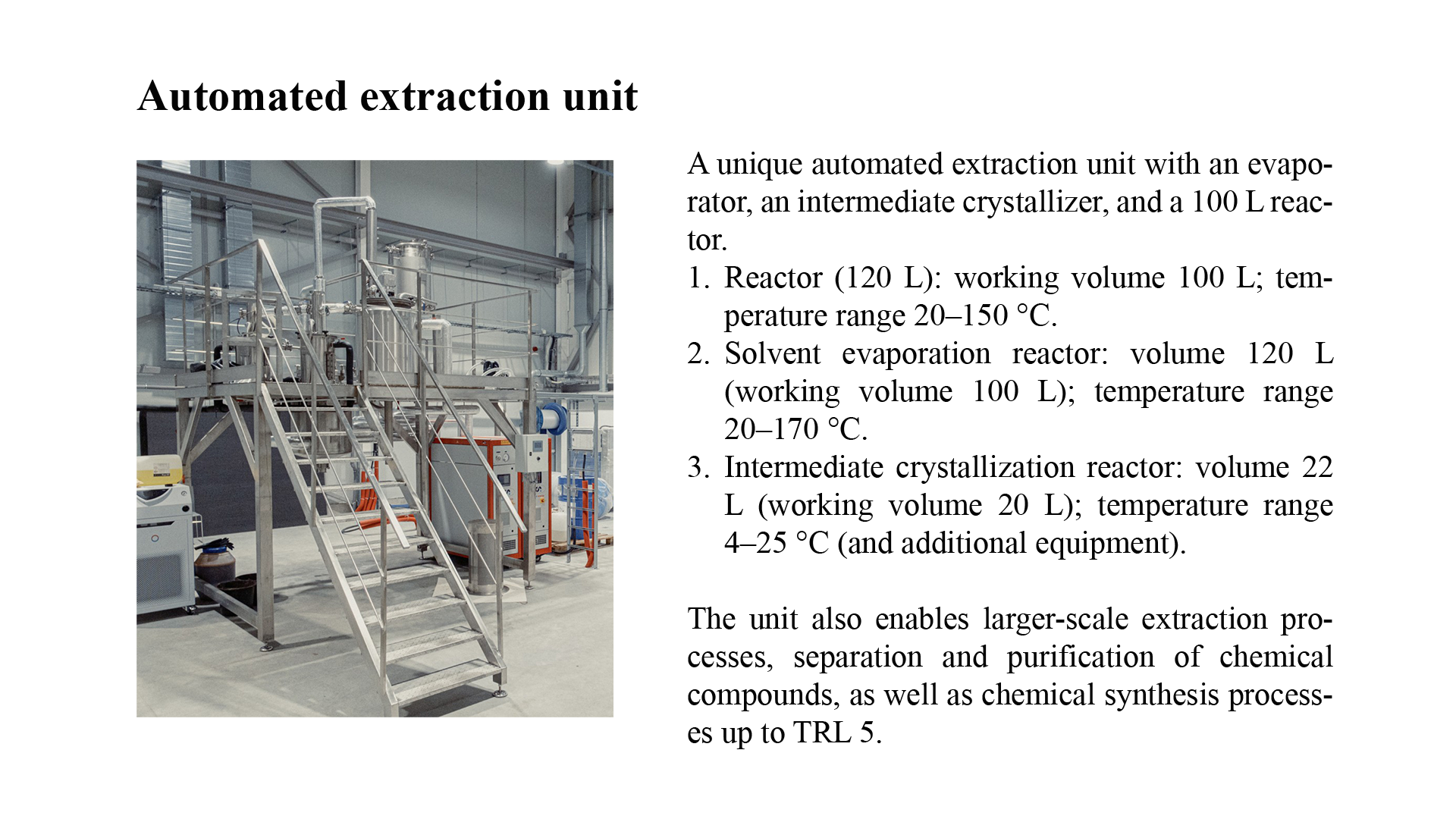

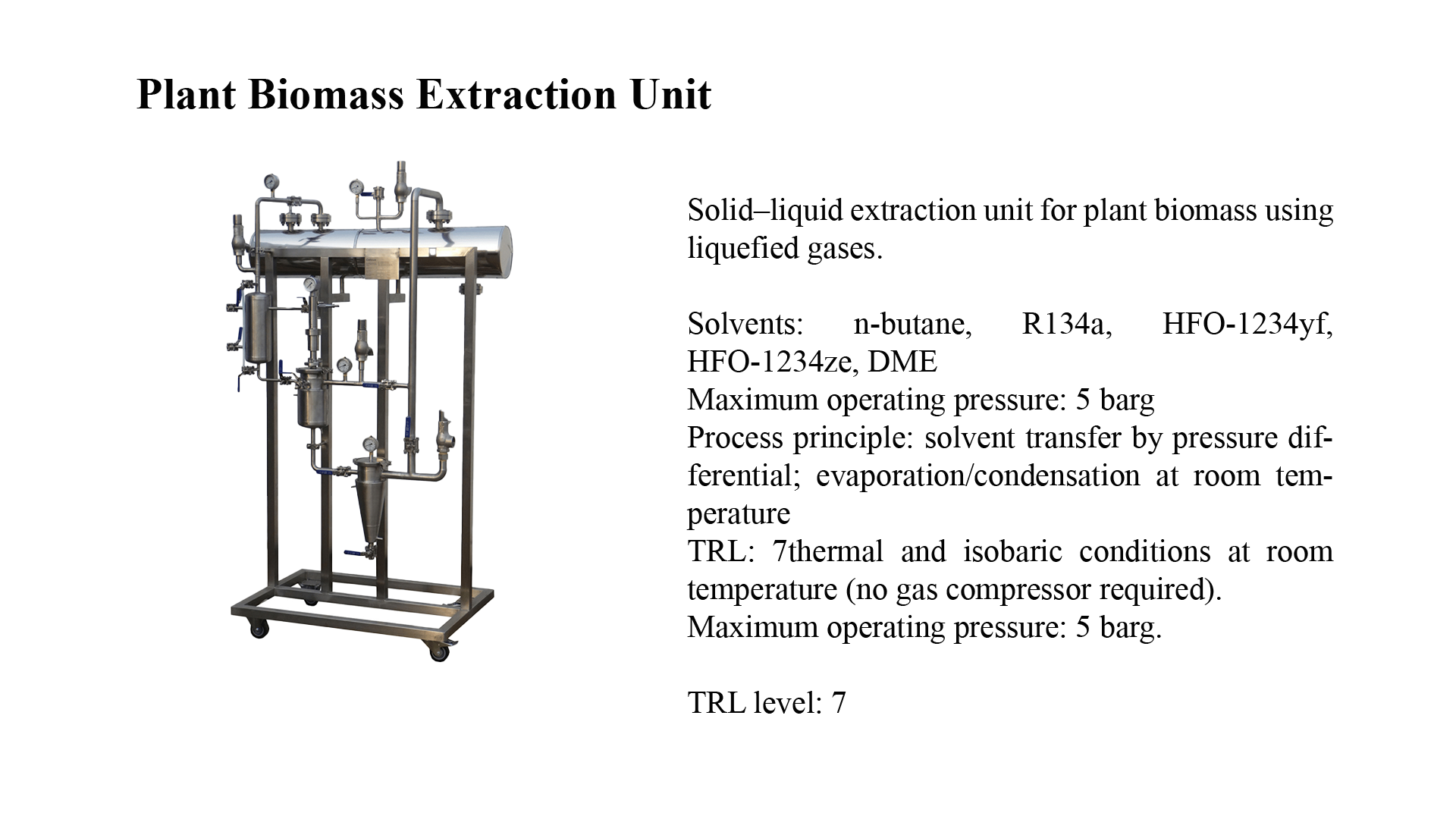

- Extraction plant (with 10 L extraction cells)

- Homogenizer for micro- / nano- cellulosis

- Electrospinning equipment

- Steam explosion equipment

- Hydrolic press

- Extraction station

- Continuous operation tunnel oven

- Fermentation plant

Hangar