BIOHYDROPACK

Project description

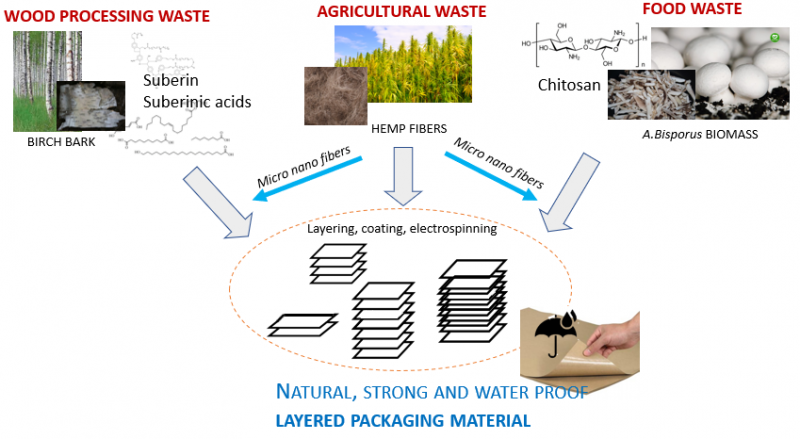

The main goal of proposed research is to create fully natural, strong and water proof layered packaging material combining hemp waste materials as fiber source and natural polymers chitosan and suberin for coatings and interlayers.

Scientific goals of proposed research are: (i) to reveal interaction of natural hydrophobic polymers chitosan and suberin, their co-working possibilities or interfering factors regarding improving hydrophobicity of fiber materials; (ii) to create natural cellulose fiber-based material with hydrophobic and unprecedented mechanical properties, competitive with synthetic packaging materials; (iii) to develop and adjust the effective and sufficient methods for layering cellulose fibers, suberin (and suberinic acids), chitosan (with and without nanocellulose filler) via electrospinning and/or casting or rolling techniques for targeted outcome – hydrophobic packaging material with maximum mechanical strength.

The biggest challenge of BIOHYDROPACK project is the compatibility of fibers and natural polymers to improve properties and ensure the maximum expression of their natural hydrophobicity properties in a newly created material at TRL 4.

Call, Activity: Latvian Council of Science Fundamental and Applied Research Project 2022/1 (LCS FARP 2023/1)

Implementation of the project

01.01.2024 - Starting of project.

30.06.2024 - Project progress report

Activity No. 1 initiated: A Data Management Plan has been prepared and published.

https://argos.openaire.eu/plans/overview/19d376a1-be23-4e16-9117-7669d41...

Activity No. 2 initiated: Hemp fiber and hemp shive cellulose fiber pulp have been obtained, and polymers have been isolated: chitosan from A. bisporus biomass and suberinic acids from birch bark.

Activity No. 5 initiated: One scientific article has been published:

Milbreta, U., Andze, L., Filipova, I., and Dortins, E. Effect of nanofibrillated cellulose on alginate and chitosan film properties as potential barrier coatings for paper food packaging, BioResources, 2024, 19(2), 3375–3389.

https://bioresources.cnr.ncsu.edu/resources/effect-of-nanofibrillated-ce...

28.12.2024 - Project progress report

Activity No. 1 – Monitoring of project activities was carried out, including meetings of project participants.

Activity No. 2 – Successfully implemented. The following were obtained:

(a) a sufficient amount of cellulose fibers from hemp shives and fibers;

(b) chitosan from A. bisporus biomass;

(c) suberinic acids from birch bark for further characterization (Activity No. 3) and application in the development of packaging materials (Activity No. 4).

Micro- and nanocellulose were produced from hemp cellulose for application in the development of multilayer packaging materials and for improving their properties.

Activity No. 3 – Characterization of the obtained raw materials was initiated using classical analytical and instrumental methods.

Activity No. 4 – Formation of hemp cellulose fiber materials was initiated using a laboratory-scale paper-forming device (Rapid-Köthen). The following tasks were carried out:

(a) preparation of base paper sheets in small quantities for preliminary trials;

(b) investigation of the effect of grammage (basis weight) on tensile index with the aim of identifying the optimal maximum strength of hemp fiber paper;

(c) testing of base coatings using the biopolymers chitosan and suberinic acids;

(d) initiation of a study on the suitability of chitosan for coating formation using the electrospinning technique.

Activity No. 5 – One scientific article has been published:

Ulla Milbreta, Laura Andze, Juris Zoldners, Ilze Irbe, Marite Skute, and Inese Filipova, Exploring the Potential of Locally Sourced Fungal Chitosan for Paper Mechanical Property Enhancement, Journal of Renewable Materials.

https://doi.org/10.32604/jrm.2024.057663

The project research results were presented at one conference:

K. Jansons, D. Harusova, M. Kovarova, L. Lovecka, U. Milbreta, L. Andze, I. Filipova, D. Hausner, Potential Applications of Electrospun Chitosan as Main Component in Developing Hydrophobic Layers for Packaging Materials, Baltic Polymer Symposium 2024, September 17–19, 2024, Birštonas, Lithuania, Abstract Book, p. 79.

30.06.2025 – Project Progress Report

Activity No. 1

Monitoring of project activities was carried out, including meetings of project participants.

The Data Management Plan was updated. The project profile was maintained in the free, open-access digital repository Zenodo:

https://zenodo.org/communities/biohydropack/records?q=&l=list&p=1&s=10

Activity No. 3

Characterization of the obtained hemp fibers was performed using a FiberTester (Lorentzen & Wettre), a freeness degree °SR measurement device (FRANK-PTI), centrifugation to determine water retention capacity, and indirect mechanical property evaluation by producing fiber handsheets and determining their properties.

Characterization of chitosan was carried out using a Vario MACRO CHNS elemental analyzer, FTIR Nicolet iS50, potentiometric titration, viscometry, and a D8 Advance diffractometer.

Characterization of suberinic acids was conducted using chemical analysis (titration, total phenolic content (TPC), ash content), chromatography (HPLC), spectroscopy (FTIR), and standardized hydrolysis methods (NREL).

Activity No. 4

Work on the production of fiber handsheets/paper was continued. Coatings of various thicknesses and combinations based on chitosan and suberinic acids were prepared. Mechanical properties and surface properties were tested.

Activity No. 5

The project research results were presented at one conference:

Ulla Milbreta, L. Andze, J. Rizikovs, I. Filipova. Chitosan and Suberinic Acids Coating Interaction Improves Paper Hydrophobic Properties. 21st International Conference on Renewable Resources and Biorefineries, 2–4 June 2025, Turku, Finland.

Public outreach was carried out via the LVKĶI website:

“LVKĶI is developing paper that is not afraid of water and is environmentally friendly”

https://kki.lv/aktualitates/lvkki-top-papirs-kas-nebaidas-no-udens-un-draudzejas-ar-dabu

31.12.2025 – Project Progress Report

Activity No. 1. Project Management

Monitoring of project activities was carried out, including meetings of project participants.

The Data Management Plan was updated. The project profile was maintained in the free, open-access digital repository Zenodo:

https://zenodo.org/communities/biohydropack/records?q=&l=list&p=1&s=10

Activity No. 2. Fiber and Polymer Extraction – Completed

Activity No. 3. Fiber and Polymer Characterization – Completed

Activity No. 4. Development of Packaging Materials

To evaluate alternative sources of chitosan, chitosan was extracted from dead bees and applied to improve the properties of packaging products (selected product model: egg cartons). The results were compared both with the effects of chitosan additives obtained from other resources and with commercially available packaging products of the same type. The results were summarized in a scientific article submitted for publication in the journal Carbohydrate Polymer Technologies and Applications.

A study on the feasibility of multilayer paper formation was initiated, evaluating the effects of layer thickness, number, and composition on the properties of the resulting material, including mechanical properties, air permeability, surface properties, and hydrophobicity. Hemp fiber layers were used to achieve improved mechanical strength, while interlayers were formed from chitosan to enhance moisture resistance. Papers consisting of 1–5 layers were produced. Work on summarizing the results for publication was initiated.

Activity No. 5. Communication and Dissemination of Results

The project research results on the use of chitosan extracted from dead bees to improve the properties of packaging products were compiled into a scientific article submitted to the journal Carbohydrate Polymer Technologies and Applications entitled:

Apis mellifera (Honeybee) as a Local Source of Chitosan to Enhance Mechanical Properties of Moulded Pulp Egg Boxes.

The supplementary files accompanying the article (Research data_supplementary) were uploaded to the project’s Zenodo profile.