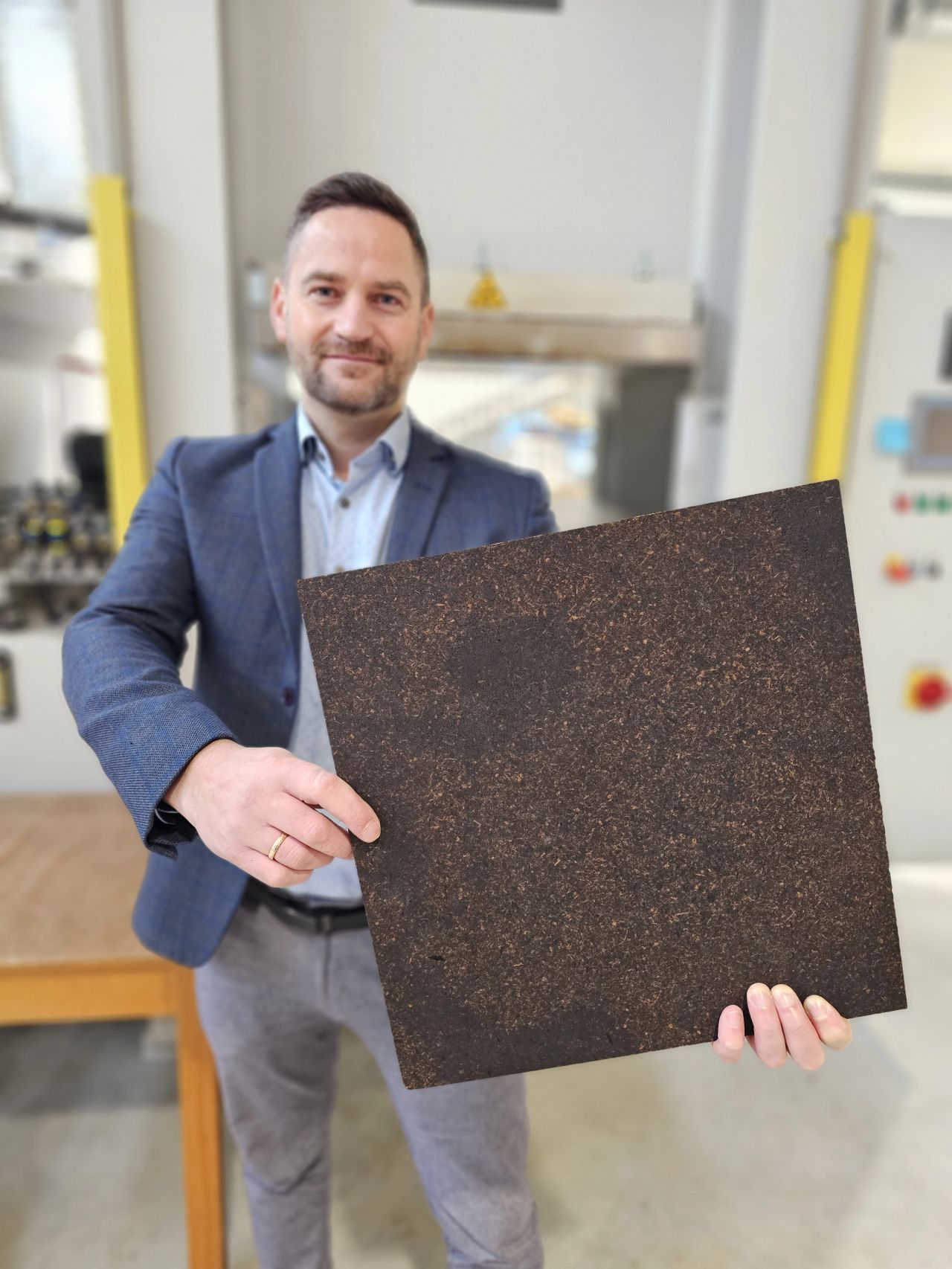

A new material developed in the BarkBuild project

Researchers of the Latvian State Institute of Wood Chemistry in cooperation with the "BarkBuild" project partnershave developed a high-density, moisture-resistant panel for the building industry. The material is obtained from the solid residues of the extraction of birch bark suberinic acids and spruce bark polyphenols. Both by-products were mixed in a particular ratio and pressed under high temperature to achieve the optimal result.

The use of wood processing residues for the production of new composite materials is an important step to implement the principles of the bioeconomy.

Practical production of the composite material is an important result of the project, which demonstrates the applicability of the developed technologies. In the LSIWC pilot equipment, a high-density, moisture-resistant panel was made from natural raw materials, which enables abandoning synthetic materials in everyday life and making buildings more ecological. In this way, both the environment and human health are protected.

The "ForestValue" ERA-NET program project "Tree bark as a renewable source of wood protection materials for building applications (BarkBuild)" started in March, 2022 with the aim to develop new wood protection and building materials based on industrially available tree bark waste. Six partners cooperate in the project - the Latvian State Institute of Wood Chemistry, Stockholm University (Sweden), CoE InnoRenew (Slovenia), Warsaw University of Life Sciences (Poland), NIBIO (Norway), VTT (Finland).

Project home page