A Composite Material with a Mission: From Agricultural Residues to the Future of Food Packaging

Environmentally friendly, biodegradable, and recyclable food packaging materials are currently one of the world’s top priorities. According to Eurostat data, in 2022, plastic packaging waste in the European Union reached 16.1 million tonnes, making plastic the second most significant packaging material after paper and cardboard. This volume accounted for approximately 19% of the total packaging waste, which stood at 83.4 million tonnes. Globally, packaging is the main source of plastic waste, representing around 40% of the world’s plastic waste.

The new EU Packaging and Packaging Waste Regulation (PPWR) stipulates that, starting in 2030, all packaging must comply with recyclability classes A, B, or C:

- Class A: ≥95% recyclable

- Class B: ≥80% recyclable

- Class C: ≥70% recyclable

Moreover, Class C packaging will be gradually phased out by 2038.

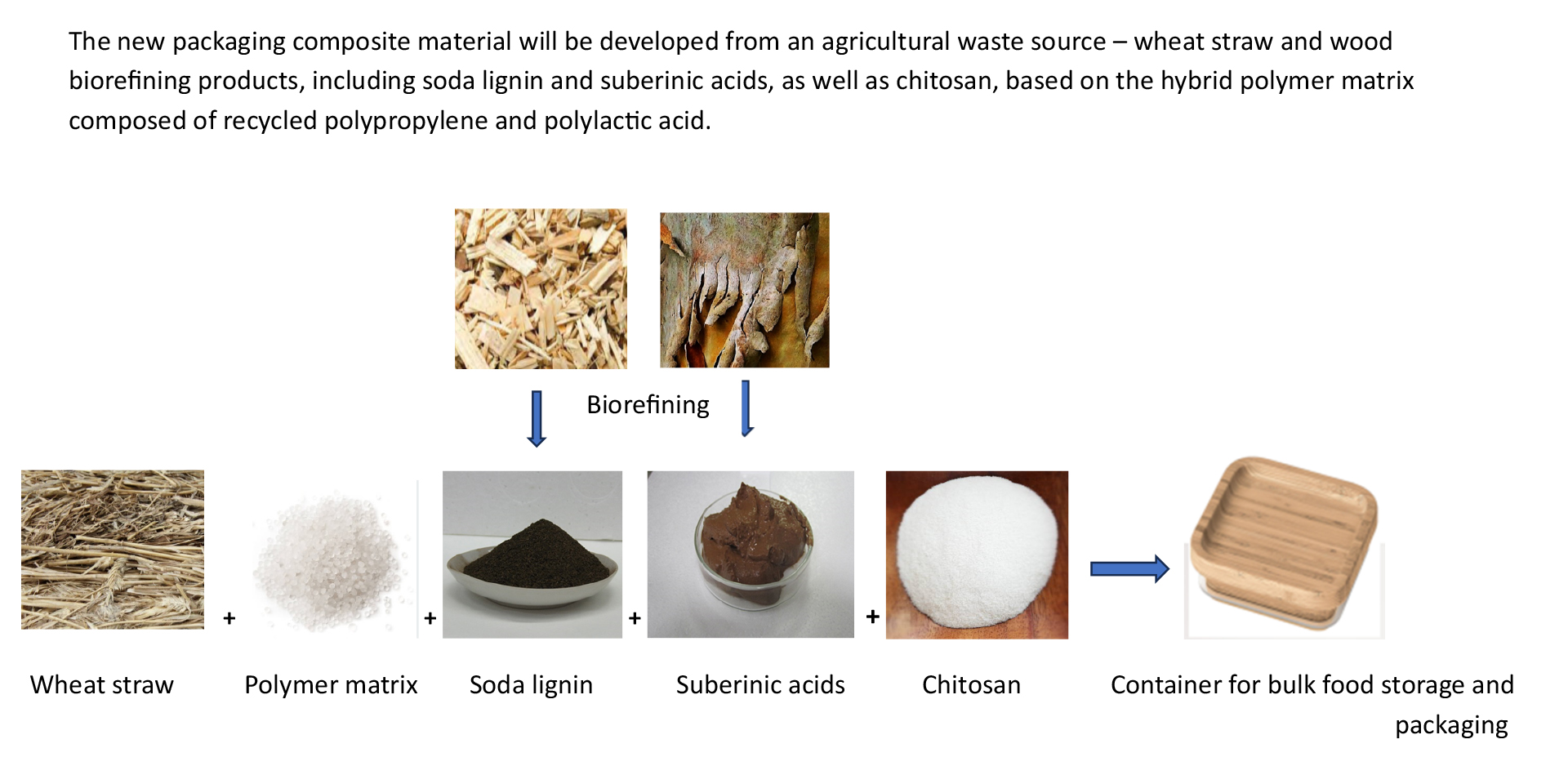

In response to the challenges and demands of our time, the Latvian State Institute of Wood Chemistry researchers are developing an innovative packaging material that combines recycled polymers, wheat straw, and functional bio-based additives derived from soda lignin and suberinic acids extracted from wood biorefinery residues.

The project focuses on the design of an innovative wheat straw-reinforced composite material based on a hybrid polymer matrix with functional bio-based additives from lignocellulosic by-products and its processing technology for the obtaining of containers for bulk food storage and packaging for decreasing the negative effects of used plastic packaging on the environment.

The foundation of this new packaging material is a hybrid polymer matrix that blends recycled polypropylene (rPP) with biodegradable polylactic acid (PLA). This matrix is filled with modified wheat straw—an agricultural residue that, when properly processed, becomes a valuable raw material. In addition, functional additives obtained from wood refinery by-products—specifically valorised soda lignin and extracted suberinic acids—are used. Researchers are developing a zero-waste lignin valorisation technology for obtaining an effective compatibilizer, and they are optimising the extraction conditions of suberinic acids with a defined chemical composition and plasticizing properties, to be used as lubricants in processing (Figure 1).

This project addresses one of the European Union’s strategic innovation priorities—developing packaging solutions based on biodegradable and recycled materials. It is part of a broader mission: to transform the packaging industry by reducing its environmental footprint while adding value to local biomass resources.

The Project Leader Dr.habil.chem. Galija Šuļga:

The investigations into the project began on January 2, 2024. The first part of the study focused on extracting lignin from both the original and alkali pre-treated birch sawdust through soda delignification. The extracted soda lignin samples were characterized by their elemental and functional compositions, utilizing analytical methods (following TAPPI protocols) and instrumental techniques (FTIR, UV, Py-GC/MS, dynamic light scattering), and were compared. The alkali pre-treatment of the sawdust reduced the content of acidic and methoxyl groups in the soda lignin when compared to the chemical composition of the lignin from the original sawdust, while increasing the yield of soda lignin and pulp from the treated sawdust. Regardless of the pH, the average sizes of the colloidal particles of soda lignin from the hydrolyzed sawdust were larger than those from the original residue, which was attributed to a more cross-linked structure of the lignin molecules extracted from the hydrolyzed sawdust.

The extraction of suberinic fatty acids from outer birch bark was conducted using various extraction media. The optimal depolymerization conditions for extracting the suberinic acids from the bark were identified. The obtained samples of suberinic acids were characterized by their elemental and functional compositions, as well as through liquid chromatography and differential thermal analysis (DTA).

At this stage, we study the co-valorization of soda lignin and chitosan for obtaining functional bio-additives using the mechanochemical method in a planetary ball mill. The research involves varying the mass ratio of the components, the choice of a radical initiator, and the pH. Additionally, we examine the technological parameters of the co-valorization process, including speed and duration.

The research results are included in the master's thesis of a research assistant Valerija Kudrajvceva, who is a master's student at the Faculty of Medicine and Life Sciences of the University of Latvia. The thesis will be defended in the first decade of June, 2025.

Growth Forecast for the Biodegradable Packaging Market

- Market size: In 2022, the global biodegradable packaging materials market was valued at approximately USD 88 billion. It is projected to reach USD 169 billion by 2032, with an annual growth rate of 6.8% CAGR. (Source: Custom Market Insights, 2023)

- Regional growth: The Asia-Pacific region is expected to be the fastest-growing market, while Europe remains the largest due to strict environmental regulations and high consumer awareness of sustainable solutions. (Source: EIN Presswire, 2023)

Figure 1