International Collaboration in Green Composite Development

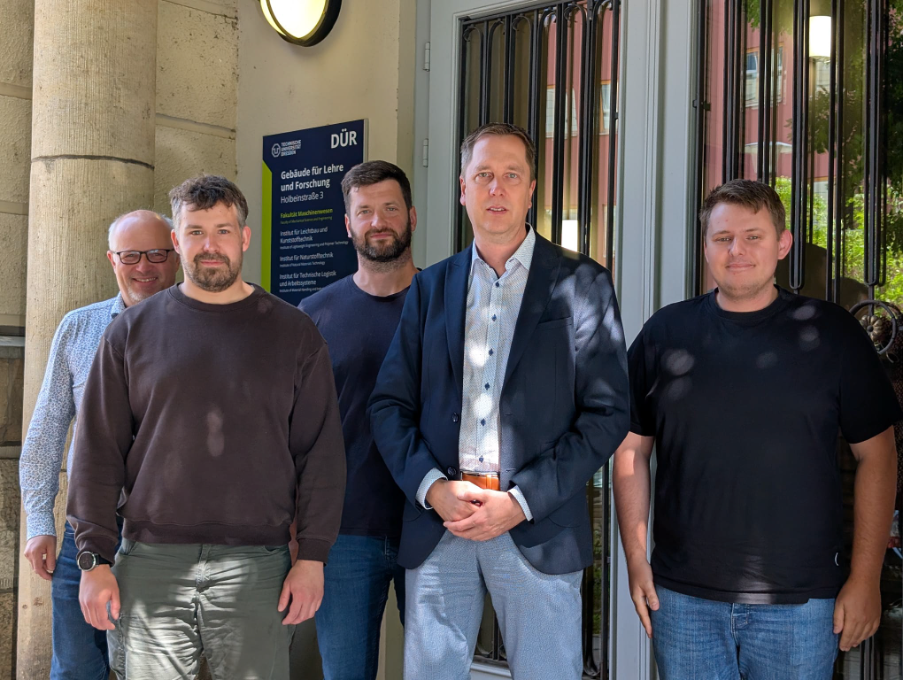

From June 9 to 13, TReResin researcher Arnis Āboliņš visited the Institute of Lightweight Engineering and Polymer Technology (ILK) at TUD Dresden University of Technology in Germany. The visit took place within the framework of the Green Compass project, in which the Latvian State Institute of Wood Chemistry is a partner. This international initiative brings together European expertise to develop environmentally friendly materials and energy-efficient production processes.

Green Compass (full title: Green materials and energy-efficient processes for circular composite products by utilising regional potentials and pan-European partnerships) is a transnational collaboration platform that supports the development of new sustainable composite materials by harnessing regional resources, green raw materials, and energy-efficient technologies. The project fosters knowledge and practical experience exchange among researchers and industry actors across Europe, strengthening the circular economy and advancing innovative material solutions.

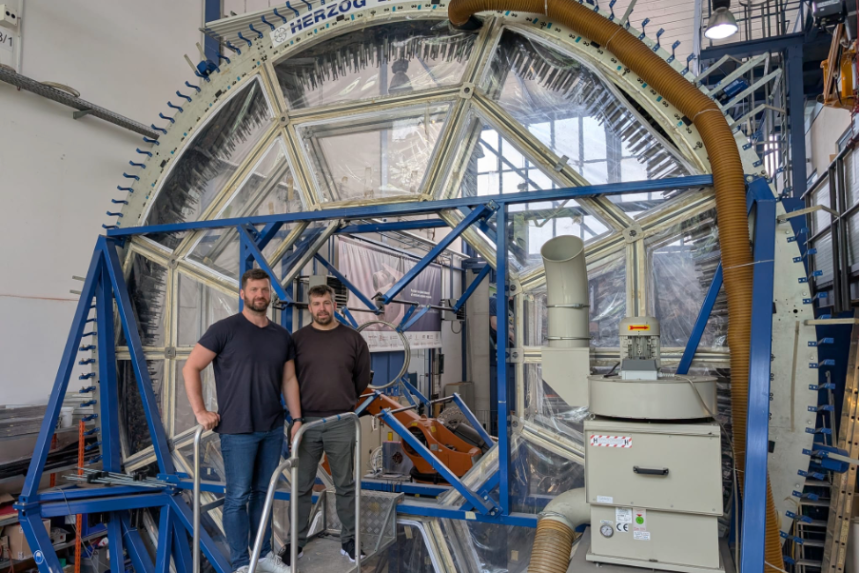

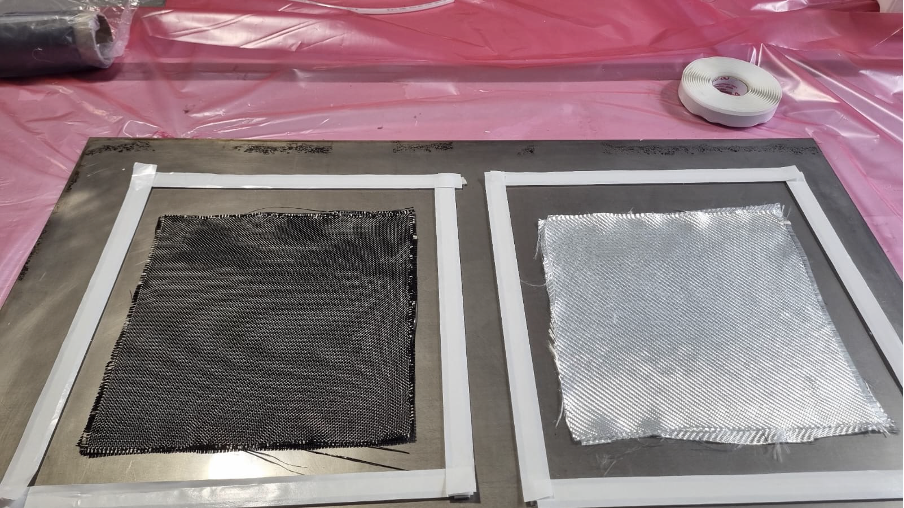

During the visit, Arnis gained hands-on experience in composite material development, focusing on thermoset polymer processing using both pressing and infusion-based technologies. He also had the opportunity to work with various equipment, including a winding machine for textile and carbon fibres.

This experience will be highly valuable for the implementation of the TReResin project (project No. lzp-2024/1-0333), which aims to develop a novel green composite based on a vitrimeric resin system derived from used cooking oil and bio-based fibres. The resulting material is expected to have high added value and application potential in the transport and electronics sectors.

(from left) Dr.-Ing. Albert Langkamp, Ph.D student, researcher at TReResin, LSIWC Arnis Abolins, Ph.D student Peteris Cabulis, Prof. Dr.-Ing. habil. Maik Gude, Dipl.-Ing. Rafał Stanik

Winding machine for carbon and textile fiber

|

|

|

|

|

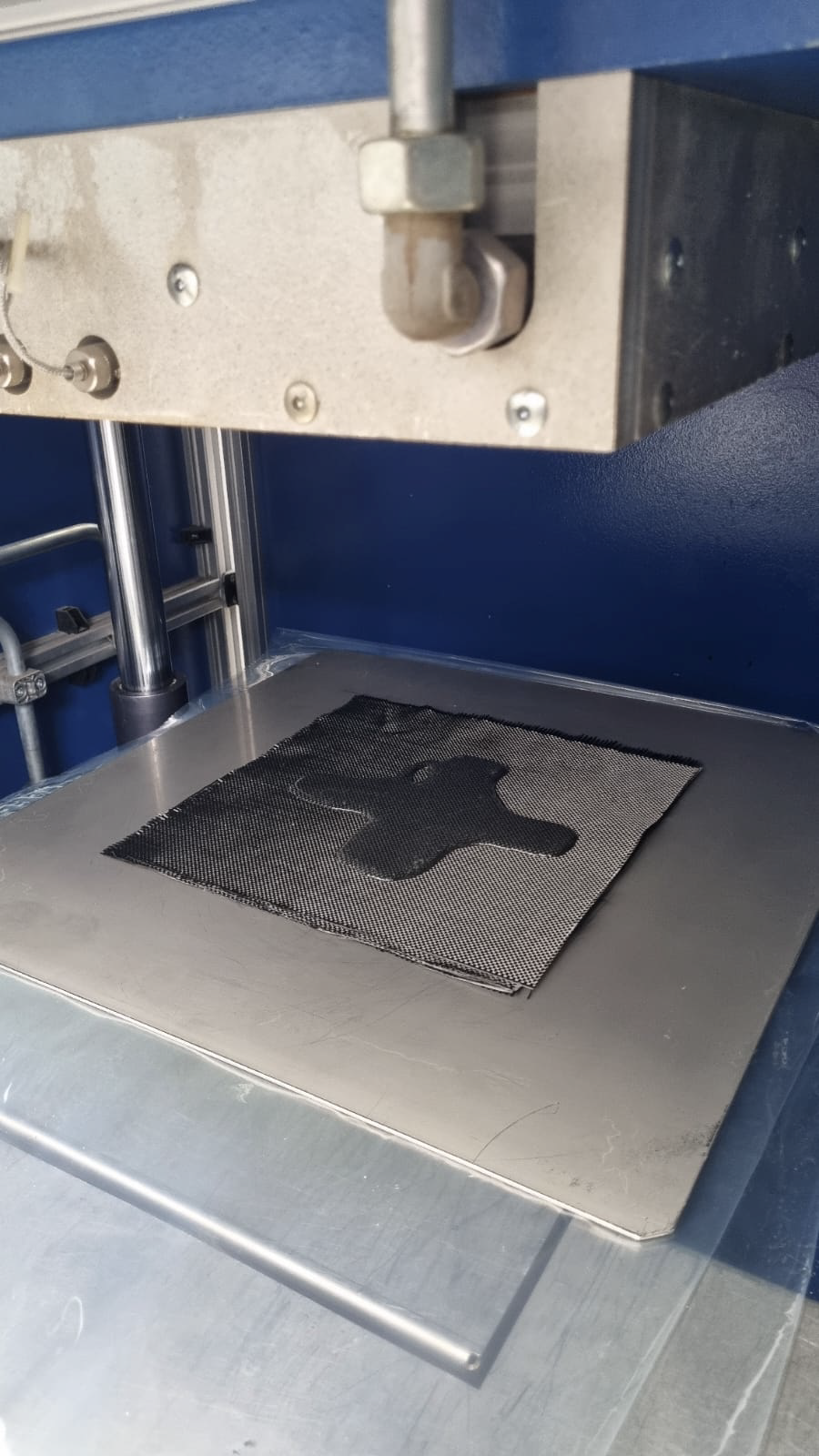

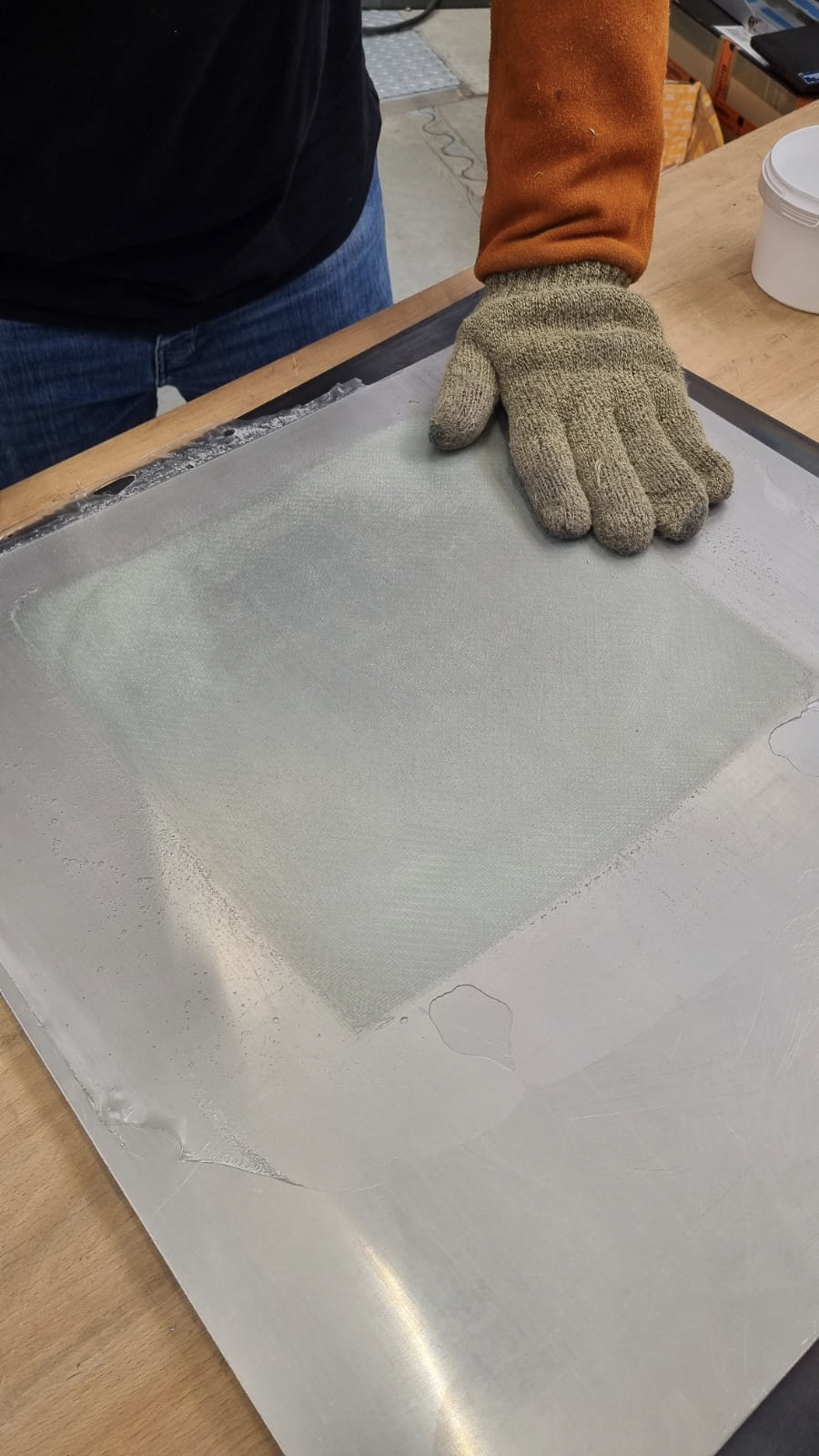

The composite materials were manufactured using the hot pressing method, where heat and pressure are applied simultaneously to cure and shape the material. This technique produces lightweight, high-strength composites with good surface quality, commonly used in automotive, aerospace, and electronics applications.

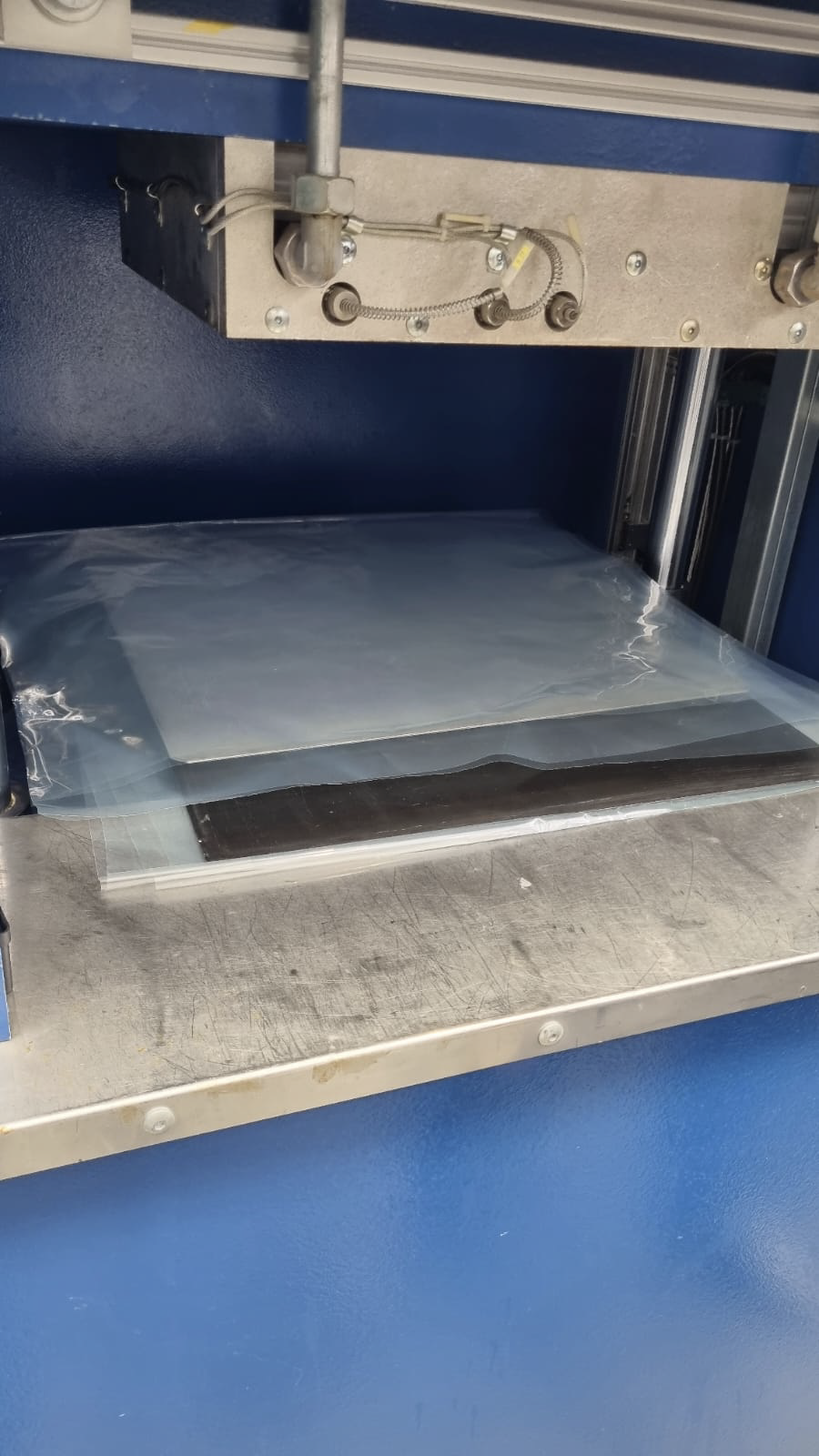

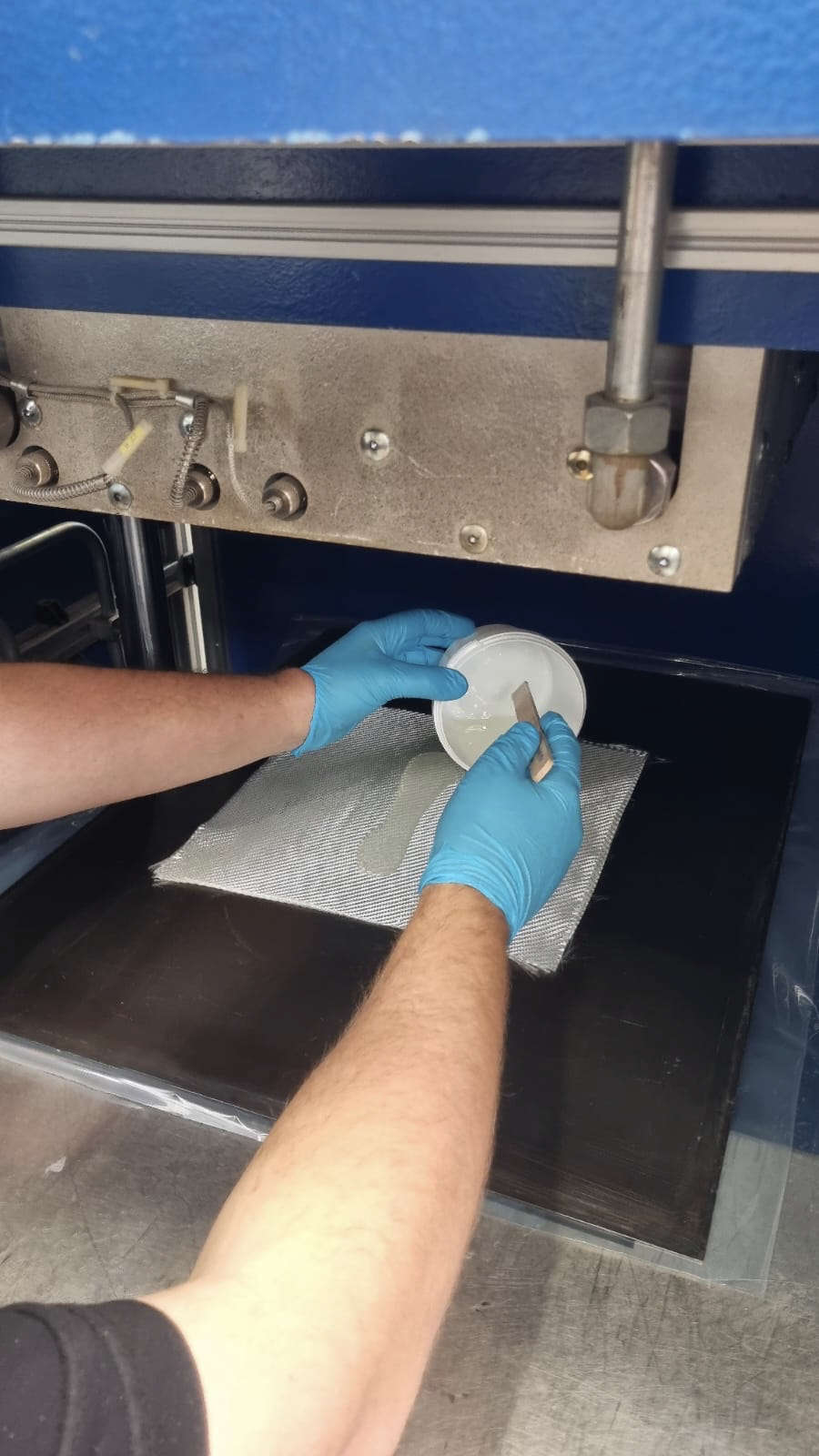

The composite materials were manufactured using the infusion method, where resin is drawn into dry fiber reinforcement using vacuum pressure. This technique ensures a high fiber-to-resin ratio, reduces voids, and produces strong, lightweight composite parts commonly used in the aerospace and automotive industries.

Project description: TReResin